Business process-oriented IT solutions at the German Electron Synchrotron

This project involved implementing business process-oriented IT solutions for the German Electron Synchrotron (DESY).

Last modified:

This project involved implementing business process-oriented IT solutions for the German Electron Synchrotron (DESY).

Last modified:

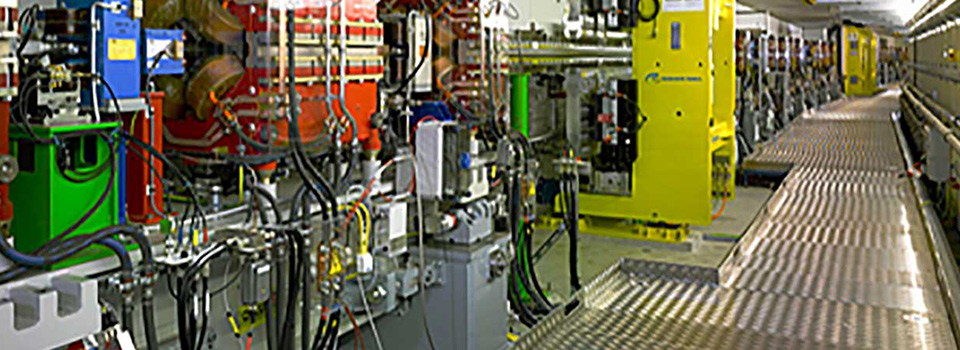

Nowadays, hardly any organization can manage without IT support for its business processes. In addition to companies and public authorities, this also increasingly affects research organizations, which often have the size and complexity of a medium-sized company or even exceed it. At the German Electron Synchrotron (DESY) in Hamburg, for example, around 2,500 employees and 3,000 visiting scientists work in the fields of accelerator construction and operation, photon research, and particle and astroparticle physics.

As part of the DESY internal projects “GO” and “KDS,” DESY has been cooperating with Fraunhofer IESE since 2011, where the methodological introduction of information systems, and in particular requirements engineering with the modeling of business processes and system architectures, are among the main areas of research and work. The aim is to promote the mutual exchange of experience in the field of business process-oriented IT solutions and to optimize methodological approaches for the sustainable introduction of corresponding concepts.

As part of the project “GO – Business Process Optimization Using an Identity and Access Management System,” DESY intends to lay the organizational and technical foundations for handling business processes more efficiently and transparently. In order to establish the methodological conditions, business processes were first recorded and analyzed so that they could be mapped electronically after the introduction of a suitable software solution (BPM Suite) and made accessible via a central end-user portal.

In addition to systems for holistic business process support, DESY also uses special information systems for documenting and coordinating engineering tasks in plant construction and operation. One of these systems, a cable documentation system (KDS), serves as a central source of information at DESY for the manufacture and documentation of cable installations.

In another joint project, DESY and Fraunhofer IESE developed an operating and functional concept for the KDS for its future operation and possible expansion stages. To this end, Fraunhofer employees collected and analyzed the current operating requirements and necessary functional enhancements for use in future projects. One of these projects aims not only to document the KDS, but also to use it in the early cable planning processes.