Hardware bottlenecks are the invisible anchors dragging down modern automotive development. As Software Defined Vehicles (SDVs) grow in complexity, development teams often find themselves stalled, waiting for access to physical test rigs like the NXP GoldBox. At Fraunhofer IESE, we have decided to break these chains. In this article, we reveal how we combined QEMU emulation with a clever “Trojan Horse” booting strategy to achieve high-performance hypervisor validation in a fully virtualized environment. Discover how we are moving the lab to the laptop, reducing hardware dependency to zero, and massively accelerating the validation of Xen hypervisors.

In the race to build the software-defined vehicles, speed is the only metric that matters. We are engineering safety-critical systems that will define the next generation of mobility, pushing the boundaries of what cars can do. But for many development teams, this high-speed race hits a sudden, grinding halt the moment they need to validate their code. The obstacle isn’t a lack of talent or complexity in the software; it’s an invisible anchor dragging down the process: the hardware.

For years, working with automotive hypervisors has meant being tethered to a physical test bench. You write your code, you build your stack, and then you wait. You wait for a specific board to become available, or you struggle with complex remote access to a lab halfway across the world. At Fraunhofer IESE, we faced this exact bottleneck. Our work on the Xen hypervisor required constant, rigorous testing on the NXP GoldBox, a powerful, specialized piece of hardware. But relying on a physical box for every single build and integration test was slowing us down. It created a dependency that we couldn’t afford.

We asked ourselves a simple but ambitious question:

What if we could break the chain?

What if we could take the exact software stack intended for high-performance automotive silicon and run it entirely in a virtual world?

What if we could validate our hypervisors on a standard laptop, anywhere, at any time?

This is the story of how we built a “Virtual GoldBox”, which helped in decoupling our innovation from the metal and ushering in a new era of virtual validation.

Building the Virtual GoldBox: ARM64 Emulation with QEMU

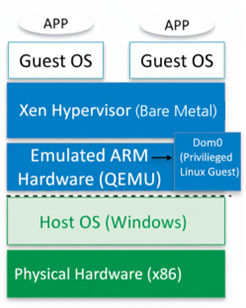

To break the hardware chain, we turned to QEMU (Quick Emulator), a powerful tool that acts as a universal translator for computers. It allows a standard laptop processor (x86) to “speak” the language of the automotive world (ARM AArch64). Our goal was to build a “Virtual GoldBox”, an environment that was indistinguishable from the physical NXP hardware as far as the software was concerned.

But we weren’t just trying to run a simple application. We needed to replicate a complete, complex stack. We had to layer a host operating system (like Windows or Linux), run the emulator on top of it to create a virtual „bare metal,“ and then install the Xen Hypervisor directly onto that emulated metal. In this setup, Xen runs exactly as it would on the real chip. It manages memory, it handles interrupts, and it spins up the privileged domain (Dom0).

The “Trojan Horse” Strategy: Overcoming EFI Boot Constraints

However, getting there wasn’t as simple as pressing “install.” Virtualization tools are typically designed to boot standard operating systems, like Linux or Windows, immediately. They aren’t naturally inclined to boot a hypervisor first. The standard boot process expects to find a kernel, not a complex virtualization layer like Xen. We had to get creative. We needed a way to intercept the boot process before the operating system took over.

Our solution was a bit of a digital trick: an “autoboot” trick. Instead of modifying the deep, complex source code of the emulator, we worked with the EFI firmware, the very first thing that runs when a machine wakes up. We took the Xen binary and disguised it as the default boot application (BootAA64.efi).

Essentially, we created a “Trojan Horse”. When the virtual machine powers on, it looks for the default bootloader, expecting to start Linux. Instead, it unknowingly loads Xen. Once inside, Xen takes command. It reads its configuration file, initializes the hardware, and then manually pulls up the Linux kernel (Dom0) as a guest. By the time the Linux login screen appears, Xen is already running the show underneath.

Comparison: Physical Hardware vs. Virtual GoldBox Validation

To illustrate why this shift is so significant, we have compared the two approaches:

| Feature | Physical Test Bench (NXP GoldBox) | Virtual GoldBox (QEMU-based) |

|---|---|---|

| Availability | Limited (scheduled lab time) | Unlimited (any laptop, any time) |

| Setup Time | Days (cabling, remote access) | Seconds (loading a disk image) |

| Portability | Static (tied to a specific location) | Fully Portable ("Lab in a File") |

| Risk Factor | Risk of "bricking" hardware | Zero risk (snapshot & restore) |

| Platform | Specialized hardware only | OS Independent (Windows/Linux) |

Transforming Automotive Validation: The Impact of Virtualization

Getting Xen to boot in this emulated environment was a major step forward. By establishing this „Virtual GoldBox,“ we unlocked capabilities that have significantly streamlined our automotive software validation process.

-

Zero Hardware Dependency:

The most immediate win is freedom. We have effectively broken the reliance on physical test benches. Our developers no longer need to schedule time on a scarce resource or wait for hardware shipments. The bottleneck is gone. If you have a laptop, you have a GoldBox.

-

A “Lab in a File”:

Perhaps the most powerful aspect of this setup is its portability. The entire environment — the Xen hypervisor, the Dom0 kernel, and the configuration — is encapsulated in a single disk image file. This means onboarding a new developer doesn’t take days of hardware setup. We simply share the image, and they are ready to code. We have turned a complex physical rig into a shareable digital asset.

-

True Platform Independence:

QEMU acts as a great equalizer. It doesn’t matter whether our engineers prefer a Windows desktop or a Linux workstation. The underlying “Virtual GoldBox” remains identical. We are running a consistent, emulated ARM64 environment on top of any host operating system. This ensures that our validation results are consistent, regardless of the machine the developer is using.

-

From Terminal to Testbed:

This virtual setup enabled us to build a comprehensive “Virtual Testbed”. We moved away from the tedious process of manually typing cryptic commands to manage domains. Instead, we can now utilize a graphical interface (a custom monitoring tool) to visualize the system state and manage the hypervisor intuitively. This lowers the barrier to entry, allowing engineers to focus on validation results rather than wrestling with terminal syntax.

-

Accelerated Hypervisor Validation:

Most importantly, this allows us to validate the hypervisor itself. We aren’t just testing applications; we are testing the virtualization platform that supports them. We can crash the kernel, corrupt the bootloader, and push the system to its limits, all without the fear of “bricking” expensive physical equipment.

Conclusion: Shifting Validation from the Lab to the Laptop

The automotive industry is evolving rapidly. As vehicles become more defined by their software than their mechanical parts, our development tools must evolve with them. At Fraunhofer IESE, we believe that you don’t always need metal to test the metal. By combining the power of QEMU with a strategic boot configuration, we created a robust, scalable environment for Xen validation that lives entirely in software.

This project wasn’t just about saving time or money; it was about empowering our engineers to innovate faster. We have moved the validation process from the lab to the laptop, proving that with the right virtualization strategy, the only limit to what we can test is our imagination.

The hardware chain is broken. Now, we build.

Accelerate Your SDV Development

Are you looking to accelerate your software-defined vehicle development by breaking hardware dependencies? Contact our Virtual Engineering team to learn more about our simulation environments and hypervisor expertise.